PTO Solenoid Repair

My bush hog would not turn. I could turn it by hand and the hose fittings were opening properly. I verified that I was receiving proper voltage at teh solenoid and even ran new grounds and 12 volts directly from the battery but no luck. Once before, my valve had stuck but simple disassembly and moving the plunger by hand freed it up. No luck this time but the valve appeared not to be opening properly. A pressure gauge on the PTO verified that I slowly got pressure to 3000 PSI. I decided that the valve must be bad. Terry recommended pulling the PTO Pressure Relief Valve and checking that. It looked OK. Fortunately, I had the bad valve that PT had replaced when I bought my used tractor. It was brutal for a reasonably precise hydraulic part but I had to use vise grips clamped very tightly to remove the lower half of the cartridge assembly from the upper half. Then I needed to use a dead blow hammer on the spring end to free the plunger. After disassembly and cleaning, I could see the valve work properly when I reassembled the cartridge. The lower half had thread sealant on it when I tore it apart but I was not comfortable doing so. When I repair the other cartridge, I will use the LokTite super glue style hydraulic thread sealer on it. I have used the stump grinder for 4 hours since the repair. |

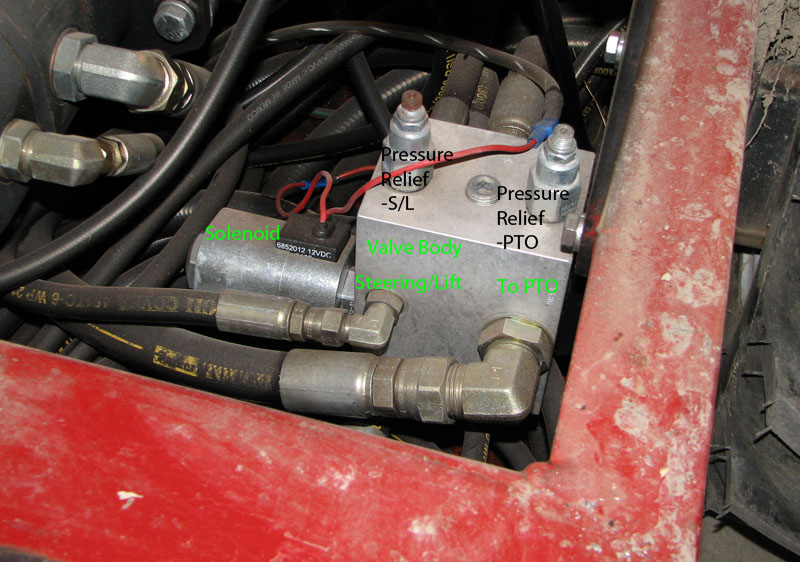

Here is a picture showing where the PTO solenoid is located:

|

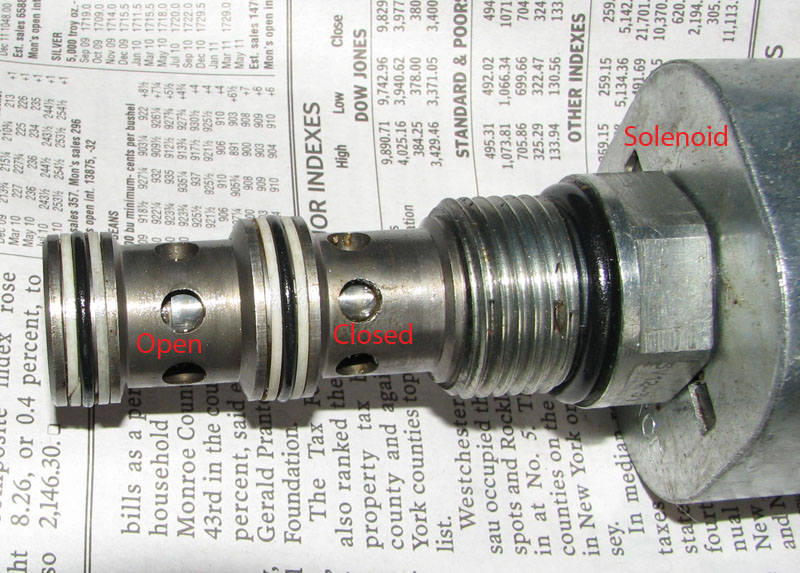

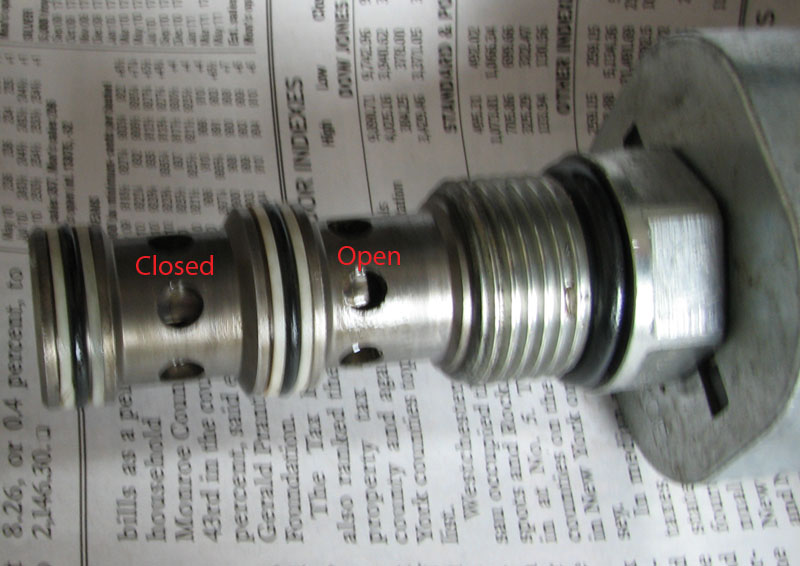

Here are pictures showing the valve off and then on. The opening is not very much, not even 1/4 of the port. Sorry for the poor 2nd picture.

|

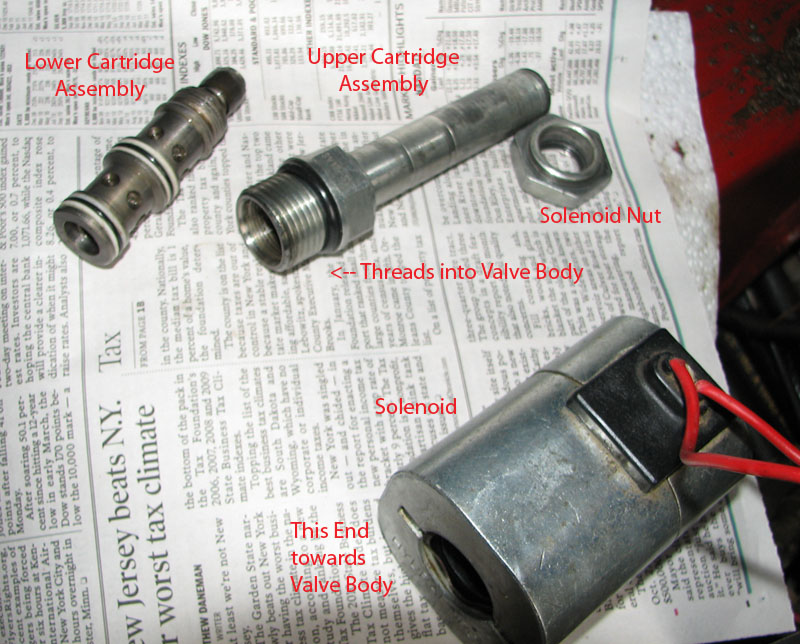

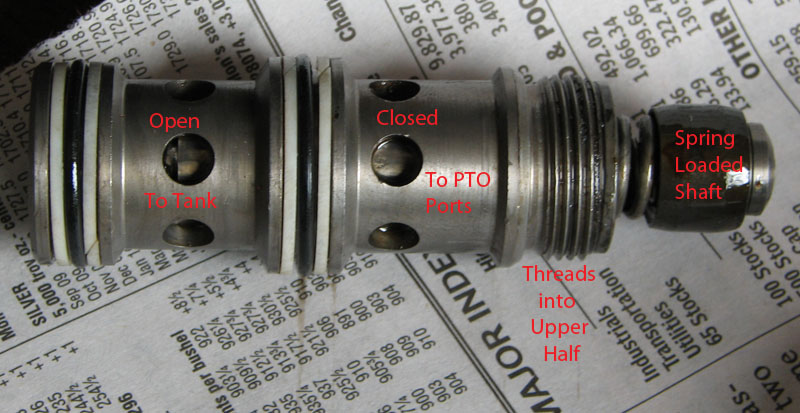

Here is the valve cartridge disassembled:

|

This shows the lower half of the valve cartridge:

|

I apologize - I did not take a picture of the internal plunger nor of the end of the valve. If I remember, I will take pictures of these when I repair the other valve. |